Screen Print

Pad Print

Digital Print

Digital Rotary Printing (including Gloss Finish)

Laser Engraving

Embroidery

Transfer Embroidery

Debossing

Foil Debossing

Sublimation Print

Digital Transfer

Woven Label

Silicone Badge

Metal Badge

PU Badge

Screen Print

How it works:

A stencil (screen) is created for each colour in the design. Ink is pushed through the mesh screen onto the product using a squeegee. Each colour is applied separately, with drying between layers. Works best for bold designs and solid colours.

Suitable for:

Flat or slightly curved surfaces such as tote bags, t-shirts, hoodies, folders, drink bottles, umbrellas, binders, and some packaging.

Advantages:

-

Vibrant, opaque colours, even on dark materials.

-

Long-lasting and durable for repeated use and washing.

-

Cost-effective for medium to large production runs.

-

Works on many substrates including fabric, plastic, and metal.

Limitations:

-

Not ideal for very fine gradients or photographic images.

-

Additional colours increase cost and production time.

-

Set-up time is longer for small quantities.

Artwork Requirements:

-

Vector artwork (.ai, .eps, .pdf).

-

Spot colours specified in Pantone (PMS).

-

Minimum line thickness: 0.3mm.

-

Avoid very small text under 2mm height.

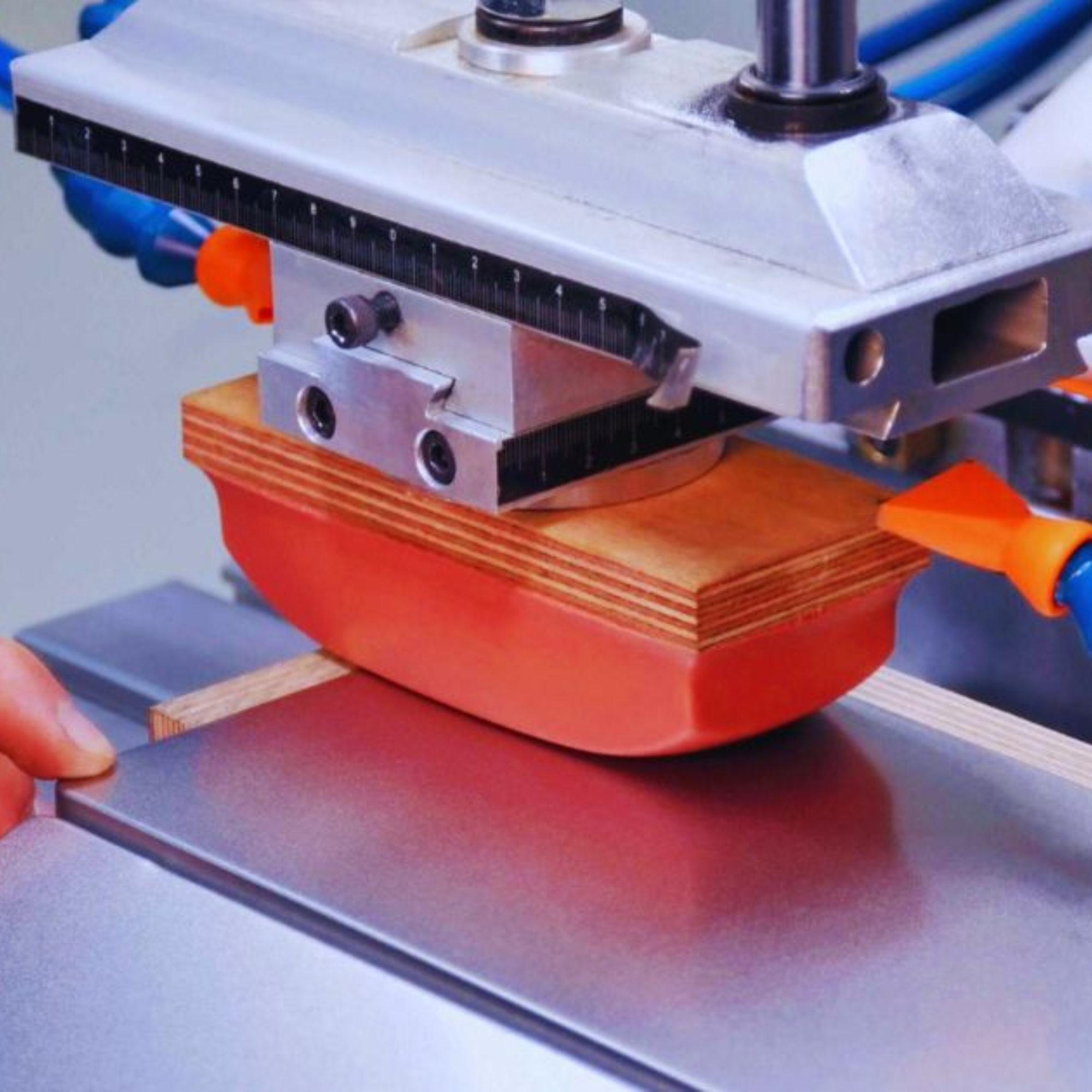

Pad Print

How it works:

A recessed plate is filled with ink. A soft silicone pad picks up the ink and transfers it onto the product. The flexible pad adapts to uneven, curved, or textured surfaces.

Suitable for:

Pens, USB drives, keyrings, stress balls, golf balls, bottle openers, and other small promotional items.

Advantages:

-

Can print on irregular or curved surfaces.

-

Good for small and intricate designs.

-

Cost-effective for small to medium runs.

Limitations:

-

Smaller print areas than screen printing.

-

Limited to spot colours (no gradients).

-

Each colour is printed separately, which can slightly misalign on very fine details.

Artwork Requirements:

-

Vector format (.ai, .eps, .pdf).

-

PMS spot colours.

-

Minimum line thickness: 0.2mm.

-

Avoid halftones or shading effects.

Digital Print

How it works:

Uses high-resolution inkjet or UV printing directly onto a flat surface. Can produce full-colour designs including gradients, photographs, and complex patterns in one pass.

Suitable for:

Flat-surfaced items like name badges, signs, power banks, notebooks, and plaques.

Advantages:

-

Full-colour CMYK printing without colour limits.

-

Can include gradients, shading, and photographic images.

-

No separate setup for multiple colours.

Limitations:

-

Durability depends on the coating of the product.

-

Works best on light-coloured or white surfaces.

Artwork Requirements:

-

High-resolution (300dpi) raster files (.jpg, .png, .tiff) or vector files.

-

CMYK colour mode.

-

Avoid RGB files to ensure accurate colour.

Digital Rotary Printing (including Gloss Finish)

How it works:

Specialised digital printers rotate cylindrical items during printing, applying high-resolution, full-colour designs around the entire product. A gloss coating can be added for durability and a premium look.

Suitable for:

Mugs, drink bottles, tumblers, glassware, and travel cups.

Advantages:

-

Full 360° wrap coverage.

-

Can produce complex photographic designs.

-

Gloss finish improves durability and visual appeal.

Limitations:

-

Limited to cylindrical items.

-

Requires product to have a consistent diameter along print area.

Artwork Requirements:

-

High-resolution CMYK files at 300dpi.

-

Use the product’s print template for exact sizing and positioning.

Laser Engraving

How it works:

A laser beam etches the design into the product surface by removing a thin layer of material. The result is a precise, permanent mark in the underlying substrate colour.

Suitable for:

Metal pens, stainless steel drinkware, keyrings, tools, leather goods, and certain wooden products.

Advantages:

-

Extremely durable and long-lasting.

-

Professional and high-end finish.

-

Fine detail possible.

Limitations:

-

No colour – engraving reveals base material tone.

-

Colour contrast depends on material composition.

Artwork Requirements:

-

Vector artwork (.ai, .eps, .pdf).

-

Solid shapes only; no gradients.

-

Minimum line thickness: 0.2mm.

Embroidery

How it works:

The design is digitised into a stitch pattern. High-speed embroidery machines stitch thread directly into the fabric.

Suitable for:

Caps, polo shirts, jackets, uniforms, bags, towels, blankets.

Advantages:

-

Premium and professional look.

-

Long-lasting even after frequent washing.

-

Works on textured fabrics where print may not adhere.

Limitations:

-

Detail limited by thread thickness.

-

Higher cost for large designs due to increased stitch count.

Artwork Requirements:

-

Vector file or high-res image for digitising.

-

Digitising fee applies for new designs.

-

Minimum text height: 4mm.

Transfer Embroidery

How it works:

An embroidery-style design is printed onto a transfer material and heat-pressed onto fabric. Mimics the look of embroidery without stitching into the garment.

Suitable for:

Caps, bags, jackets, and uniforms.

Advantages:

-

Detailed designs possible without heavy stitching.

-

Can apply to areas difficult for embroidery machines.

Limitations:

-

Not as durable as stitched embroidery.

-

May peel after extended wear or washing.

Artwork Requirements:

-

Vector or high-res (300dpi) CMYK files.

-

Avoid overly fine details for better longevity.

Debossing

How it works:

A custom metal die is pressed into the material to create a recessed impression of the design.

Suitable for:

Leather, PU, notebooks, diaries, packaging.

Advantages:

-

Subtle, elegant, and tactile.

-

Permanent marking with no fading.

Limitations:

-

No colour – purely an indentation.

-

Best for bold, simple designs.

Artwork Requirements:

-

Vector artwork.

-

Minimum line thickness: 0.4mm.

-

Avoid fine text.

Foil Debossing

How it works:

Similar to debossing, but metallic foil is applied during the process for a shiny, premium effect.

Suitable for:

Luxury leather goods, gift boxes, premium notebooks.

Advantages:

-

Adds metallic or coloured shine.

-

Eye-catching and high-value appearance.

Limitations:

-

Foil can wear off over time.

-

Flat surfaces work best.

Artwork Requirements:

-

Vector artwork.

-

Minimum line thickness: 0.5mm.

-

Avoid small or intricate details.

Sublimation Print

How it works:

Special sublimation ink is printed onto transfer paper, then heat-pressed. The heat turns the ink into gas, which permanently dyes the surface.

Suitable for:

Polyester fabrics, mugs, mouse pads, lanyards, sportswear.

Advantages:

-

Full-colour photographic printing.

-

Won’t peel, crack, or wash out.

-

Wrap-around printing possible on certain products.

Limitations:

-

Works only on white/light polyester or polymer-coated products.

-

Not suitable for dark fabrics without special coating.

Artwork Requirements:

-

High-resolution CMYK file at 300dpi.

-

Provide at actual print size.

-

Avoid low-resolution images to prevent pixelation.

Digital Transfer

How it works:

Design is digitally printed onto special transfer film and applied to the product with heat and pressure.

Suitable for:

Sportswear, promotional apparel, bags, and uniforms.

Advantages:

-

Full-colour reproduction, including gradients and photographs.

-

Suitable for detailed designs on textured fabrics.

Limitations:

-

Edge film may be slightly visible.

-

Not as long-lasting as direct print for heavy-use garments.

Artwork Requirements:

-

CMYK file at 300dpi.

-

Provide at final print size.

Woven Label

How it works:

Design is woven directly into a fabric label using coloured threads, then sewn into or onto the product.

Suitable for:

Clothing, hats, bags, and premium textile items.

Advantages:

-

Professional and long-lasting.

-

Handles detailed patterns and multiple colours.

Limitations:

-

Small text may be hard to read.

-

Thread colours are fixed to available PMS matches.

Artwork Requirements:

-

Vector artwork.

-

PMS thread colours specified.

-

Minimum text height: 3mm.

Silicone Badge

How it works:

Soft silicone is moulded into raised or recessed shapes. Badge is heat-applied to the product.

Suitable for:

Sportswear, outdoor gear, backpacks, headwear.

Advantages:

-

3D tactile effect.

-

Flexible, waterproof, and washable.

Limitations:

-

Cannot achieve extremely fine details.

Artwork Requirements:

-

Vector file.

-

Maximum line thickness: 0.5mm.

Metal Badge

How it works:

Metal is die-struck or cast, plated, and optionally enamel-filled. Attached with a pin, clasp, or adhesive.

Suitable for:

Lapel pins, awards, name badges, membership tokens.

Advantages:

-

Premium, durable, and long-lasting.

-

Custom shapes possible.

Limitations:

-

Higher setup costs.

-

Longer production times.

Artwork Requirements:

-

Vector file.

-

PMS enamel colours if applicable.

PU Badge

How it works:

Polyurethane badge is moulded into a flat or raised design, then sewn or heat-applied.

Suitable for:

Jackets, bags, uniforms, headwear.

Advantages:

-

Lightweight, flexible, durable.

-

Available in various finishes.

Limitations:

-

Less heat-resistant than silicone badges.

Artwork Requirements:

-

Vector file.

-

Minimum detail: 0.4mm.